About Wire Straightening Machines and Cutting Machines

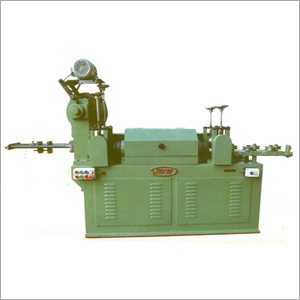

Wire Straightening Machines and Cutting Machines

Technical Specifications

| Model | Storm-12 |

| In thickness of wire | 4 to 12mm |

| In length of wire to be cut automatically | 50 to 1000mm length increased as per requirement |

| Feeding capacity per min. | 60' feet |

| Power of Motor H.P. | 10 H.P & 1 H.P |

| Required R.P.M | 1440 |

| Approx. Weight in Kg. | 1000 |

| Floor space required | 60'x22' |

Precision and VersatilityThese machines are designed to handle diverse wire materials and diameters, delivering cutting lengths tailored to project requirements. The advanced straightening technology assures excellent accuracy within 0.5 mm, minimizing waste and rework.

High Productivity with Smart ControlWith speeds reaching up to 40 meters per minute, the integration of PLC-based control systems provides automated, user-friendly operation and precise monitoring. This capability streamlines production for semi-automatic and fully automatic workflows.

Robust Safety and SupportOperators can rely on comprehensive safety mechanisms, including emergency stop and overload protection. Every machine comes with onsite installation and training, fostering safe usage and swift onboarding for teams.

FAQs of Wire Straightening Machines and Cutting Machines:

Q: How does the wire straightening and cutting process work in these machines?

A: The machine continuously feeds wire through alloy steel straightening dies, aligning and rectifying any bends. A PLC-controlled system then measures the preset cutting length (from 50 mm up to 6,000 mm), and the blade, driven mechanically or electrically, executes a precise, low-tolerance cut.

Q: What types of wire materials and diameters can the machines handle?

A: These machines are capable of processing a wide variety of wires, including mild steel, stainless steel, aluminum, and copper, with supported wire diameters from 0.5 mm to 8 mm for both inlet and outlet.

Q: When is onsite installation and training provided?

A: Onsite installation and training are scheduled following the delivery of your machine. Our specialists ensure proper setup and operational training for your staff, promoting efficient and safe usage from day one.

Q: Where can the wire straightening and cutting machines be utilized?

A: This equipment is ideal for construction sites, machinery production, and fabrication industries where precise wire processing and high-throughput operations are essential for structural components, frames, or custom parts.

Q: What benefits does the PLC-controlled system bring to wire processing?

A: A PLC-controlled system enhances precision, repeatability, and safety. Operators enjoy easy customization of cutting lengths and real-time error monitoring, resulting in reduced downtime and improved consistency in production output.

Q: How does the machine ensure operator safety during operation?

A: Operator safety is addressed via features such as emergency stop and overload protection, while the air-cooled system helps maintain optimal temperatures and noise levels below 65 dB, contributing to a safer work environment.