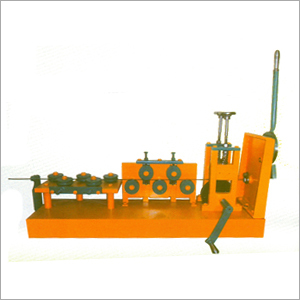

About Manual Wire Straightning Cutting Machine

Owing to our in-depth expertise in this domain, we are engaged in offering an extensive range of Manual Wire Straightning Cutting Machine. This ensures effortless raising and lowering backgrounds. Under the stern guidance of our adroit professionals, this is manufactured with the use of the finest quality materials. Offered machine is rigorously tested by our diligent quality experts before its dispatching. As per the variegated requirement of our clients, we provide this Manual Wire Straightning Cutting Machine in different specifications at pocket-friendly price.

Features:

- Hassle-free operation

- Optimum performance

- Longer service life

Cutting-Edge Precision and VersatilityThis machine allows operators to adjust wire cutting lengths from 1 inch up to 10 feet, accommodating a broad range of fabrication tasks. The roller-based straightening mechanism ensures each wire segment is exceptionally straight before cutting, resulting in high-quality finished products for fabrication shops and workshops.

Simplified Operation and MaintenanceHand lever operation makes this model user-friendly and energy-efficient, requiring no electrical power. The low-maintenance construction and easily accessible servicing points reduce downtime, while a powder-coated surface ensures long-term resistance to corrosion and wear.

Robust Construction and Safety FeaturesCrafted from mild steel with a blue or custom-colored finish, the machine is both durable and aesthetically versatile. Important safety measures such as the protective cover and locking system minimize operator risk, providing a safe and controlled work environment in industrial applications.

FAQs of Manual Wire Straightning Cutting Machine:

Q: How do I adjust the cutting length on this manual wire straightening and cutting machine?

A: Changing the wire cutting length is simpleuse the adjustment mechanism to set your desired length, ranging from 1 inch to 10 feet, depending on your project requirements. The clear scale and settings enable straightforward changes for different wire segments.

Q: What type and size of wire can this machine process?

A: This machine accommodates metal wires with diameters between 2 mm and 6 mm. It is well-suited for various applications in wire fabrication workshops and industrial manufacturing units.

Q: When does this machine require maintenance, and is it easy to service?

A: The machine is designed for low maintenance, thanks to its sturdy components and powder-coated finish. Regular inspection of the roller mechanism and blade sharpness is advised. Servicing points are easily accessible, making routine maintenance quick and straightforward.

Q: Where is the ideal place to install this wire straightening and cutting machine?

A: Installation is floor-mounted, suitable for workshops, fabrication shops, or industrial spaces with sufficient working area. The machines compact footprint (approx. 1200 x 450 x 900 mm) fits most standard industrial layouts.

Q: What is the operational process for straightening and cutting wire with this device?

A: Feed the wire through the guide and roller mechanism. Use the hand lever to initiate straightening, followed by the cutting operation. The process is manual, allowing precise control over each stage, with safety features ensuring operator safety throughout.

Q: What are the main benefits of using this manual machine in wire fabrication?

A: Key advantages include adjustable cutting lengths for flexibility, low noise operation, robust safety measures, and manual operation requiring no electricity. The efficient output speed (up to 30 meters per minute) increases productivity while maintaining high quality.