About Wire Straightening Polishing Machines

Wire Straightening Polishing Machines

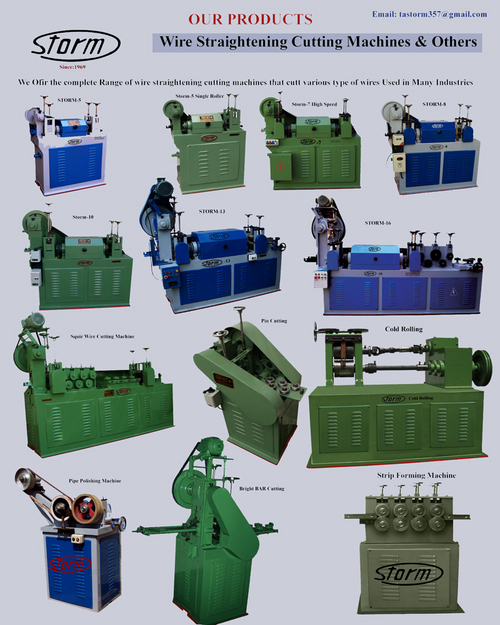

With the help of our skilled and experienced professionals, we are recognized as one of the most prominent manufacturers of Wire Straightening polishing machines. Precisely engineered using advanced technology and quality stainless steels, we are offering these machines as per industrial standards. Appreciated for their robust construction, easy installation and fine finish, these Wire Straightening polishing machines are used in various industries. Our quality auditors regularly checks these machines on various quality parameters to offer flawless delivery to clients.

Precision Straightening with Superior Surface FinishAchieve exceptional straightening accuracy and surface finishing on a wide range of wire shapes, including round, square, and rectangular profiles. With surface finish options of mirror polish or matt, and a straightening tolerance of 0.2 mm, these machines are designed for applications demanding both function and aesthetics.

Automatic Operation and Adjustable ControlsOur machines are equipped with an automatic, continuous feeding system for uninterrupted production. The manual and fine adjustment mechanisms allow operators to achieve precise alignment and optimal surface finish, regardless of the wire material or profile.

Versatile Applications and Custom ConfigurationsSuitable for mild steel, stainless steel, copper, and aluminium wires, these machines can support various lengths and diameters. With customizable dimensions and color, users can select models tailored to their production space and branding requirements.

FAQs of Wire Straightening Polishing Machines:

Q: How do these wire straightening polishing machines ensure precise wire alignment and surface finish?

A: These machines utilize robust induction electric motors and advanced straightening mechanisms, achieving a tolerance of 0.2 mm. The polishing heads (one or two, depending on configuration) and fine adjustment controls enable consistent mirror or matte finishes on various wire profiles.

Q: What wire materials and shapes can be processed using this machine?

A: The machine is suitable for processing wires made of mild steel, stainless steel, copper, and aluminium. It accommodates round, square, and rectangular wire shapes, with inlet diameters ranging from 0.5 mm to 8 mm and outlet diameters from 0.4 mm to 8 mm.

Q: When should I opt for a mirror-polished versus a matt surface finish?

A: A mirror-polished finish is ideal when high reflectivity or a decorative appearance is required, often for visible or high-end applications. A matt finish is preferred for functional uses where a subdued look and reduced glare are desired.

Q: Where are these wire straightening and polishing machines manufactured, and can they be exported?

A: These machines are designed and manufactured in India, and the manufacturer regularly exports to international markets. Customizations are available to meet specific export requirements and standards.

Q: What is the typical process for operating this machine?

A: Operation begins by feeding wires into the automatic continuous system. Operators can use manual and fine adjustments to calibrate straightening and polishing settings. The process delivers finished wires at rates up to 120 meters per minute, depending on wire diameter and material.

Q: How does the machine benefit production efficiency and workplace environment?

A: With high production capacity, automatic feeding, and low noise levels under 80 dB, these machines greatly enhance efficiency and sustain operator comfort. The customizable setup ensures seamless integration into diverse manufacturing environments.

Q: What are the key usage scenarios for these machines?

A: Common applications include straightening and surface polishing of wires for construction, automotive, electrical, and decorative industriesany scenario requiring precisely aligned and polished metal wire products.